Speaker wire

Speaker wire is used to make the electrical connection between loudspeakers and audio amplifiers. Modern speaker wire consists of two or more electrical conductors individually insulated by plastic such as PVC, PE or Teflon. The two wires are electrically identical, but are marked (e.g. by a ridge on the insulation of one wire, the color of one wire, a thread in one wire, etc) to help easily identify the correct polarity.

Some historic designs also featured another pair of wires for electrical power for an electromagnet in the loudspeaker. At least one such speaker design is still in production (in France), but essentially all speakers manufactured now use permanent magnets, a practice which displaced field electromagnet speakers over half a century ago.

The effect of speaker wire upon the signal it carries has been a much-debated topic in the audiophile and high fidelity worlds. The accuracy of many advertising claims on these points has also been a matter of much debate.

Contents |

Explanation

Speaker wire is a passive electrical component described by three properties which determine its performance: resistance, capacitance, and inductance. A theoretically perfect wire has no resistance, capacitance, or inductance. The shorter a wire, the closer it comes to this, because resistance increases with the length of the conductor (except superconductors). The wire's resistance has the greatest effect on its performance.[1] The capacitance and inductance of the wire has less effect because they are insignificant relative to the capacitance and inductance of the loudspeaker. Larger conductors (smaller wire gauge) have less resistance but increased skin effect. As long as speaker wire resistance is kept to less than 5% of the speaker's impedance, the conductor will be adequate for home use.

Speaker wires are selected based on price, quality of construction, aesthetic purpose, and convenience. Stranded wire is more flexible than solid wire, and is suitable for movable equipment. For a wire that will be exposed rather than run within walls, under floor coverings, or behind moldings (such as in a home), appearance may be a benefit, but it is irrelevant to electrical characteristics. Better purification of oxidizing materials such as copper is said to result in more consistent properties throughout the length of the wire, but this is a non-issue in terms of its effect on sound quality. Better jacketing may be thicker or tougher, less chemically reactive with the conductor, less likely to tangle and easier to pull through a group of other wires, or may incorporate a number of shielding techniques for non-domestic uses.

Even with poor-quality wire, an audible degradation of sound may not exist. Many supposedly audible differences in speaker wire can be attributed to listener bias or the placebo effect. Listener bias is enhanced in no small part by the popular manufacturers' practice of making claims about their products either with no valid engineering or scientific basis, or of no real-world significance. Many manufacturers catering to audiophiles (as well as those supplying less expensive retail markets) also make unmeasurable, if poetic, claims about their wire sounding open, dynamic, or smooth. To justify these claims, many cite electrical properties such as skin effect, characteristic impedance of the cable, or resonance, which are generally little understood by consumers. None of these has any measurable effect at audio frequencies, though each matters at radio frequencies.[2]

Resistance

Resistance is by far the most important specification of speaker wire. Low-resistance speaker wire allows more of the amplifier's power to energize the loudspeaker's voice coil. The shorter the cable and the greater the conductor's cross-sectional area, the lower its resistance. Depending on the hearing ability of the listener, this resistance begins to have an audible effect when the resistance exceeds 5% of the speaker's impedance.

A speaker wire’s impedance takes into account the wire’s resistance, the wire’s path, and the dielectric properties of local insulators. The latter two factors also determine the wire's frequency response. The lower the impedance of the speaker, the greater a significance the speaker wire's resistance will have.

Wire gauge

Thicker wires reduce resistance. The resistance of 16-gauge or heavier speaker connection cable has no detectable effect in runs of 50 feet (15 meters) or less in standard domestic loudspeaker connections for a typical 8 ohm speaker.[3] As speaker resistance drops, lower gauge (heavier) wire is needed to prevent degradation to damping factor—a measure of the amplifier's control over the position of the voice coil.

Insulation thickness or type also has no audible effect as long as the insulation is of good quality and does not chemically react with the wire itself (poor-quality insulation has occasionally been found to accelerate oxidation of the copper conductor, increasing resistance over time). High-power in-car audio systems using 2-ohm speaker circuits require thicker wire than 4 to 8-ohm home audio applications.

Most consumer applications use two conductor wire. A common rule of thumb is that the resistance of the speaker wire should not exceed 5% of the rated impedance of the system. The table below shows recommended lengths based on this guideline:

| Wire size | 2 Ω load | 4 Ω load | 6 Ω load | 8 Ω load |

|---|---|---|---|---|

| 22 AWG (0.326 mm2) | 3 ft (0.9 m) | 6 ft (1.8 m) | 9 ft (2.7 m) | 12 ft (3.6 m) |

| 20 AWG (0.518 mm2) | 5 ft (1.5 m) | 10 ft (3 m) | 15 ft (4.5 m) | 20 ft (6 m) |

| 18 AWG (0.823 mm2) | 8 ft (2.4 m) | 16 ft (4.9 m) | 24 ft (7.3 m) | 32 ft (9.7 m) |

| 16 AWG (1.31 mm2) | 12 ft (3.6 m) | 24 ft (7.3 m) | 36 ft (11 m) | 48 ft (15 m) |

| 14 AWG (2.08 mm2) | 20 ft (6.1 m) | 40 ft (12 m) | 60 ft (18 m)* | 80 ft (24 m)* |

| 12 AWG (3.31 mm2) | 30 ft (9.1 m) | 60 ft (18 m)* | 90 ft (27 m)* | 120 ft (36 m)* |

| 10 AWG (5.26 mm2) | 50 ft (15 m) | 100 ft (30 m)* | 150 ft (46 m)* | 200 ft (61 m)* |

* While in theory heavier wire can have longer runs, recommended household audio lengths should not exceed 50 feet (15 m).[3]

The gauge numbers in SWG (standard wire gauge) and AWG (American wire gauge) reduce as the wire gets larger. Sizing in square millimeters is also common.

Wire material

Use of copper is more or less universal for speaker wire; it has low resistance and less cost compared to other suitable materials. Copper and aluminum both oxidize, but oxides of copper are conductive, while those of aluminum are insulating. Also offered is Oxygen-free Copper (OFC), sold in several grades. The various grades are marketed as having better conductivity and durability, but they have no significant benefit in audio applications.[3]

Silver has a slightly lower resistivity than copper, which allows a thinner wire to have the same resistance. Silver is expensive, so a copper wire with the same resistance costs considerably less. Silver tarnishes to form a thin surface layer of silver sulfide.

Gold has a higher resistivity than either copper or silver, but it does not oxidize, so it can be used for wire-end terminations. Suitably specified gold flashing has its uses for appropriate tasks, but in domestic use such flashing is not normally functional, for several reasons.

Capacitance and inductance

Capacitance

Capacitance occurs between any two conductors separated by an insulator. In an audio cable, capacitance occurs between the cable's two conductors; the resulting losses are called "dielectric losses" or "dielectric absorption". Capacitance also occurs between the cable's conductors and any nearby conductive objects, including house wiring and damp foundation concrete; this is called "stray capacitance".

Parallel capacitances add together,[4] and so both the dielectric loss and the stray capacitance loss add up to a net capacitance.

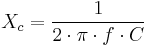

Audio signals are alternating current and so are attenuated by such capacitances. Attenuation occurs in direct proportion to frequency: a higher frequency can more easily leak through a given capacitance. The amount of attenuation can be calculated for any given frequency; the result is called the capacitive reactance, which is an effective resistance measured in ohms:

...where:

is the frequency in hertz; and

is the frequency in hertz; and is the capacitance in farads.

is the capacitance in farads.

This table shows the capacitive reactance in ohms—higher means lower loss—for various frequencies and capacitances; highlighted rows represent loss greater than 1% at 30 volts RMS:

| Capacitive Reactance | 100hz | 200hz | 500hz | 1,000hz | 2,000hz | 5,000hz | 10,000hz | 20,000hz | 50,000hz |

|---|---|---|---|---|---|---|---|---|---|

| 100pF (0.1nF) | 15,915,508 | 7,957,754 | 3,183,102 | 1,591,551 | 795,775 | 318,310 | 159,155 | 79,578 | 31,831 |

| 200pF (0.2nF) | 7,957,754 | 3,978,877 | 1,591,551 | 795,775 | 397,888 | 159,155 | 79,578 | 39,789 | 15,916 |

| 500pF (0.5nF) | 3,183,102 | 1,591,551 | 636,620 | 318,310 | 159,155 | 63,662 | 31,831 | 15,916 | 6,366 |

| 1,000pF (1nF) | 1,591,551 | 795,775 | 318,310 | 159,155 | 79,578 | 31,831 | 15,916 | 7,958 | 3,183 |

| 2,000pF (2nF) | 795,775 | 397,888 | 159,155 | 79,578 | 39,789 | 15,916 | 7,958 | 3,979 | 1,592 |

| 5,000pF (5nF) | 318,310 | 159,155 | 63,662 | 31,831 | 15,916 | 6,366 | 3,183 | 1,592 | 637 |

| 10,000pF (10nF) | 159,155 | 79,578 | 31,831 | 15,916 | 7,958 | 3,183 | 1,592 | 796 | 318 |

| 20,000pF (20nF) | 79,578 | 39,789 | 15,916 | 7,958 | 3,979 | 1,592 | 796 | 398 | 159 |

| 50,000pF (50nF) | 31,831 | 15,916 | 6,366 | 3,183 | 1,592 | 637 | 318 | 159 | 64 |

| 100,000pF (100nF) | 15,916 | 7,958 | 3,183 | 1,592 | 796 | 318 | 159 | 80 | 32 |

| 200,000pF (200nF) | 7,958 | 3,979 | 1,592 | 796 | 398 | 159 | 80 | 40 | 16 |

| 500,000pF (500nF) | 3,183 | 1,592 | 637 | 318 | 159 | 64 | 32 | 16 | 6 |

The voltage on a speaker wire depends on amplifier power; for a 100-watt-per-channel amplifier, the voltage will be about 30 volts RMS. At such voltage, a 1% loss will occur at 3000 ohms or less of capacitive reactance. Therefore, to keep audible (up to 20,000hz) losses below 1%, the total capacitance in the cabling must be kept below about 2700pF.

Ordinary lamp cord has a capacitance of 10-20 pF per foot, plus a few picofarads of stray capacitance, so a 50 foot run (100 total feet of conductor) will have less than 1% capacitive loss in the audible range. Some premium speaker cables have higher capacitance in order to have lower inductance; 100-300 pF is typical, in which case the capacitive loss will exceed 1% for runs longer than about 5 feet (10 feet of conductor).

Inductance

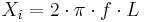

All conductors have inductance, which is their inherent resistance to changes in current. That resistance is called inductive reactance, measured in ohms. Inductive reactance depends on how quickly the current is changing: quick changes in current (i.e. high frequencies) encounter a higher inductive reactance than do slow changes (low frequencies). Inductive reactance is calculated using this formula:

...where:

is the frequency in hertz; and

is the frequency in hertz; and is the inductance in henrys.

is the inductance in henrys.

Audio signals are alternating current and so are attenuated by inductance. The following table shows the inductive reactance in ohms—lower means lower loss—for typical cable inductances at various audio frequencies; highlighted rows represent loss greater than 1% at 30 volts RMS:

| Inductive Reactance | 100hz | 200hz | 500hz | 1,000hz | 2,000hz | 5,000hz | 10,000hz | 20,000hz | 50,000hz |

|---|---|---|---|---|---|---|---|---|---|

| 0.1μH | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 0.2μH | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 |

| 0.5μH | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 | 0.2 |

| 1μH | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 | 0.1 | 0.3 |

| 2μH | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 | 0.1 | 0.3 | 0.6 |

| 5μH | 0.0 | 0.0 | 0.0 | 0.0 | 0.1 | 0.2 | 0.3 | 0.6 | 1.6 |

| 10μH | 0.0 | 0.0 | 0.0 | 0.1 | 0.1 | 0.3 | 0.6 | 1.3 | 3.1 |

| 20μH | 0.0 | 0.0 | 0.1 | 0.1 | 0.3 | 0.6 | 1.3 | 2.5 | 6.3 |

| 50μH | 0.0 | 0.1 | 0.2 | 0.3 | 0.6 | 1.6 | 3.1 | 6.3 | 15.7 |

| 100μH | 0.1 | 0.1 | 0.3 | 0.6 | 1.3 | 3.1 | 6.3 | 12.6 | 31.4 |

| 200μH | 0.1 | 0.3 | 0.6 | 1.3 | 2.5 | 6.3 | 12.6 | 25.1 | 62.8 |

| 500μH | 0.3 | 0.6 | 1.6 | 3.1 | 6.3 | 15.7 | 31.4 | 62.8 | 157.1 |

The voltage on a speaker wire depends on amplifier power; for a 100-watt-per-channel amplifier, the voltage will be about 30 volts RMS. At such voltage, a 1% loss will occur at 0.3 ohms or more of inductive reactance. Therefore, to keep audible (up to 20,000hz) losses below 1%, the total inductance in the cabling must be kept below about 2μH.

Ordinary lamp cord has an inductance of 0.1-0.2μH/foot, likewise for shielded cord[5], so a run of up to about 5 feet (10 total feet of conductor) will have less than 1% inductive loss in the audible range. Some premium speaker cables have lower inductance at the cost of higher capacitance; 0.02-0.05μH/foot is typical, in which case a run of up to about 25 feet (50 feet of conductor) will have less than 1% inductive loss.

Terminations

Speaker wire terminations are optional and largely for convenience, but may offer lower corrosion over longer periods of time. Bare wire ends work just as well electrically and may work better mechanically, as adding a termination introduces another potential point of error in installation or failure over time. The most common termination types are solder-tinned wire ends, soldered or crimped pin or spade lugs, banana plugs, and 2-pin DIN connectors. Which type to use is determined by the connectors on the equipment at each end of the wire.

Some terminations are gold plated, which is of no functional use on consumer equipment speaker lines, except to help market equipment to end users unfamiliar with the relevant principles. In a moist environment, gold-plated connectors can resist corrosion better than some other materials, although they should only be mated with other gold-plated connectors as galvanic corrosion may otherwise occur.[3]

Many speakers and electronics have flexible five-way binding posts that can be screwed down or held down by a spring to accept bare or soldered wire and pins or springy banana plugs (through a hole in the outward-facing side of the post).

There are also several types of proprietary connectors, though these are largely on all-in-one entertainment centers and bookshelf stereo systems.

In recent years, the Neutrik Speakon connector is appearing more and more on professional audio equipment. One reason is simple: in many European countries the banana plug can fit into 230 V main electrical sockets. A mistake will damage equipment, and could possibly injure or kill someone as well. Recent EU regulations prohibit banana plugs in non-AC equipment, unless equipped with a safety pin mechanism preventing insertion into a wall outlet; there is such a connector available (from WBT Connectors), but it is not widely used.

Additionally, the Neutrik speakON connector twists to lock in place, preventing one cause of intermittent failure, and accidental disconnection common in well-used banana plug connections. The speakON also carries more current than heavy-duty 15 A 0.25 in (6.4 mm) phone plugs (originally used in the telephone industry), and does not short two conductors together at insertion/removal.

High-end cables

High-end audio cables are claimed by their manufacturers to improve the sound quality of high-end audio high-fidelity systems. For analog audio interconnecting cables, basic system frequency response can be calculated from the electrical properties of the cables and components on either side of the cables. These properties include electrical resistance, capacitance and inductance. For small-signal applications the degree of shielding is also important. All of these qualities are taken into account in the design of commercial and broadcast cables. High-end cables for the audiophile market often involve intricate construction geometries and exotic materials such as silver and oxygen-free copper (long-crystal, high-purity copper).

Cables carrying digital signals such as S/PDIF and HDMI are effectively immune to signal degradation for the short lengths used in consumer audio. HDMI uses error correction which makes errors even less likely.

Quality debate

There is debate among audiophiles surrounding the impact that high-end cables have on audio systems with audibility of the changes central to the discussion. [6] [3][7]

Digital cables

One of the more contentious areas is in digital cable design, with high-end cables being sold with claims of "distortion-free signal transfer."[8]

Speaker wire

Another area of debate is speaker wire "quality". While some speaker wire marketers claim audible improvement with design or exotic materials, skeptics say that a few meters of speaker wire from the power amplifier to the binding posts of the loudspeakers cannot possibly have much influence because of the greater influence from complex crossover circuits found in most speakers and particularly from the speaker driver voice coils that have several meters of very thin wire. There is however agreement that the overall resistance of the speaker wire should not be too high.[3]

An accepted guideline is that the wire impedance should not exceed 5% of the entire circuit. For a given material, resistance is a function of length and thickness (specifically of the ratio of length to cross-sectional area). For this reason, lower impedance speakers require lower resistance speaker wire.[3] Longer cable runs need to be even thicker.[9] Once the 5% guideline is met, thicker wire will not provide any improvement.[3]

Roger Russell—a former engineer and speaker designer for McIntosh Labs—details how expensive speaker wire brand marketing misinforms consumers in his online essay called Speaker Wire - A History. He writes, "The industry has now reached the point where [wire] resistance and listening quality are not the issues any more, although listening claims may still be made....The strategy in selling these products is, in part, to appeal to those who are looking to impress others with something unique and expensive."[3]

See also

References

- ^ ProCo Sound. Whitepapers. Understanding Speaker Cables

- ^ http://sound.westhost.com/cables.htm

- ^ a b c d e f g h i j Russell, Roger (1999-2007). "Speaker Wire - A History". Roger Russell. http://www.roger-russell.com/wire/wire.htm. Retrieved 17 July 2009.

- ^ capacitance

- ^ 18-2 Shielded Cord data sheet page 1, retrieved 2011-05-24 from http://www.westpenn-wpw.com/index.php?option=com_cable_finder&func=PDF_Info&download=25293B

- ^ Jensen Transformers. Bill Whitlock, 2005. Understanding, Finding, & Eliminating Ground Loops In Audio & Video Systems. Retrieved February 18, 2010.

- ^ The Audiophile BS Page

- ^ On Jitter, the S/PDIF Standard, and Audio DACs., Norman Tracy

- ^ Audioholics: Online A/V magazine. Gene DellaSala. Speaker Cable Gauge (AWG) Guidelines & Recommendations January 21, 2008

External links

- [1] Pro Co Sound Inc. white paper

- Speaker Wire - Roger Russell (former McIntosh Laboratory loudspeaker designer) opinions on loudspeaker wiring

- Audioholics - Speaker wire gauge - "audiophile" opinion

- Crutchfield Advisor advice on standard domestic speaker installations

- Understanding In-wall Speaker Cable Ratings

- Solving Signal Problems - Belden Corp article for Broadcast Engineering magazine

- Speaker Wire - Roger Russell (former McIntosh Laboratory loudspeaker designer) opinions on loudspeaker wiring